Flow Rate Calculator 3d Printer

Flow rate calibration is extremely simple and can be completed in less than 30 minutes using the process below. Using these settings, the 3d printer figures out how fast to run the extruder motors to send enough filament for printing through the hotend.

Calibrating Filament Flow Rate To Improve 3d Print Quality - Make N Print

Our 3d printing speed calculator lets you find the maximum print speed that you can achieve with your current 3d printer configuration.

Flow rate calculator 3d printer. How to calibrate the 3d printer before an extruder change Calculate volume of stator (the room where your screw is). The new value can be set by sending the gcode command below to your printer or you can also put it into your printer firmware.

859k members in the 3dprinting community. Divide the maximum flow rate obtained in step 6, by the surface area of your normal print line obtained in step 7. You can calculate the flow rate in five simple steps:

Use this calculator correct for the expansion of the filament by adjusting the flow rate. Download our test file and import it in your slicer. Modify your existing slicers settings to match the list below.

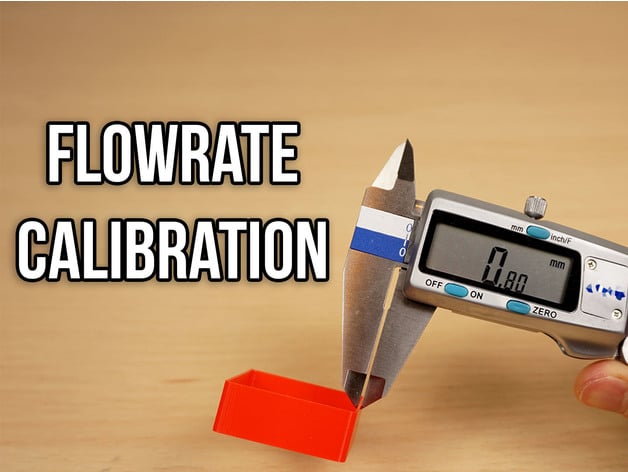

Every hotend and extruder combination has a capacity to melt and deposit a certain volume of filament every second. Why do the flow rate calibration? Hence calibrating the filament flow rate is a crucial step in 3d printing.

Learn what it is and how it can help fix print issues. If you push your printer above that limit you will get underextrusion as well as poor layer adhesion. Besides this, flow rate calibration can also improve retraction values a bit and help with bulging corners.

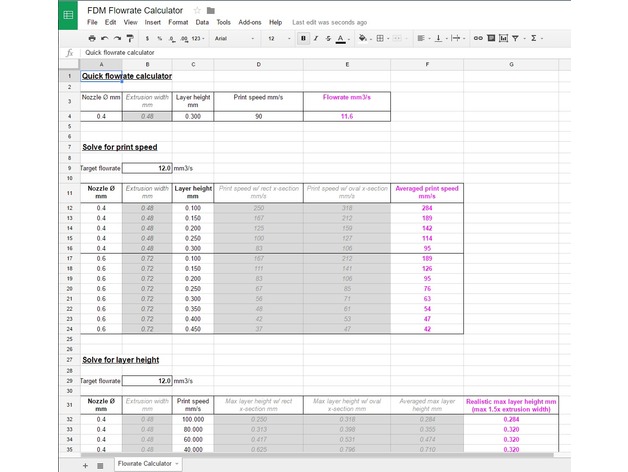

This value is a safe max printing speed for your 3d printer with the nozzle diameter, temperature and filament you previously set. If you enjoyed this guide and you want to say thank you please consider supporting me by sending a tip on thingiverse or my paypal here. How to calculate the correct flow rate (with my flow rate calculator haha) :

We start by extruding 5 cm filament at 1 mm / s and then increase the extrusion speed until the extruder starts to lose steps. If you do set the esteps with the gcode command, remember to save it to your eeprom by. Input the average velocity of the flow.

Simply enter your nozzle size, line width, layer height and choose the material you’ll be printing. This is the method i have elaborated by merging a few other methods and. Any feedback very welcome, thanks.

To do this, send the following command to your 3d printer: The calculation of the flow is carried out automatically by the 3d printer according to the steps/mm that the 3d printer manufacturer establishes for the extruder motor, depending on the diameter of the filament and the exit diameter of the nozzle. Let's take a look at cura's extrusion multiplier, which is called flow rate.

Press j to jump to the feed. Enter the values below to see how you can adjust your flow compensation to produce the properly sized line width of. /r/3dprinting is a place where makers of all skill levels and walks of life can learn about and discuss 3d.

My e3d v6 hot end starts to slip at 17 (mm)3/s, so i made a calculator so it's easy to work out what speeds/widths/layer heights i can use for prints: Naturally 3d slicer software don’t know what the individual printers requirements are. To use this calculator print a 20mm x 20mm x 20mm cube in vase mode and then measure the top 5 layers with your caliper.

The flow rate, also known as extrusion multiplier, is a slicer setting that determines the amount of plastic a 3d printer will extrude. Download files and build them with your 3d printer, laser cutter, or cnc. G1 e50 f60 (extrude 50 mm filament at 1 mm / s) repeat this step and add 60 to the f (feed rate) setting.

Just follow the steps below to get your new esteps. Especially as they can change from the same manufacture and same model of 3d printer. Nevertheless, it is not clear because of in this equation the surface of the filament it.

You can check you slicer parameters using this calculator to make sure you avoid this limit. Measure near the center of the cube not near the edges. Fr = nozzle size (mm) x layer height (mm) x print speed (mm/s) = mm3/s.

The flow rate calibration is done in order to fine tune the amount of plastic extruded by the printer. Although this generally works fine in most cases, you’ll see a big drop in print quality and consistency with bigger nozzles and layer height. Every hotend and extruder combination has a capacity to melt and deposit a certain volume of filament every second.

If you push your printer above that limit you will get underextrusion as well as poor layer adhesion. The default value for the flow rate is usually 100%. Namely the filament flow rate is the rate as which the 3d printer extrudes the molten filament.

Thingiverse is a universe of things. The slicer’s automatic calculation consider the nozzle size and increase it by 20%. The formula for calculating the extruder rotation distance value to be used in the printer.cfg file is the following:

As soon as you notice that your extruder is losing steps, you take the last value before the. Maybe reduce significant figures of answer. I found that it is possible to calculate the flow rate (fr) by the following equation:

You know have a total volume of the cavity within your extruder. This tool is to help you calibrate the esteps for your 3d printer. Π * a/2 * b/2.

Rotation_distance = * /. You can check you slicer parameters using this calculator to make sure you avoid this limit. Other way is dropping it in an measuring cylinder and measure the difference in milliliters.

A general rule of thumb accepted by 3d printer users suggest a line width up to 50% bigger than the nozzle. Printables basics buyer's guides reviews deals

What Is The Flow Of 3d Printing And How To Adjust It

Calculating Flow Rate For Your 3d Slicer - Desiquintanscom Flow Slicer 3d Printing

Swimming Pool Calculation Excel Sheet Swimming Pools Swimming Pool

Excel Sum And Offset Formula Tutorial Excel Excel Macros Positive Cash Flow

Flow Rate Calculator

Flow Rate Calibration - Improve Print Accuracy 3d Print Beginner

Pin On Cnc Things

The Best Flowrate Calibration Method By Petrzmax - Thingiverse

Flow Rate Calibration - Improve Print Accuracy 3d Print Beginner

Flow Rate Calibration - Improve Print Accuracy 3d Print Beginner

Flow Rate Calibration - Improve Print Accuracy 3d Print Beginner

Flow Rate Calibration - Improve Print Accuracy 3d Print Beginner

Mcat Physics Flashcard - Continuity Of Volume Flux Illustration Fluid Mechanics Continuity Equation In The Flow Of An Idea Fluid Mechanics Physics Mechanic

This Is A Sewing Ponyclamp For Leathercraft Some Assembly Required Update 27520 Updated Top And Bottom Parts Created To Leather Craft Craft Table Crafts

Calculating Flow Rate For Your 3d Slicer - Desiquintanscom

Calibrating Filament Flow Rate To Improve 3d Print Quality - Make N Print

Extrusion Flowrate Calculator By Luckypants - Thingiverse

The Best Flowrate Calibration Method By Petrzmax - Thingiverse

Specific Fuel Consumption

You have just read the article entitled Flow Rate Calculator 3d Printer. You can also bookmark this page with the URL : https://naomijez.blogspot.com/2021/06/flow-rate-calculator-3d-printer.html

0 Response to "Flow Rate Calculator 3d Printer"

Post a Comment